Lee VanBibber - Management

All right, here’s what we got. We’ve got a situation brewing on the floor. It seems the chips are stale and we’re not sure which station is out of control. We pulled some bags from our storage area and did a sample and we’re seeing the same problem.

I need you to walk the floor and check the data for the mean, r chart, plus upper and lower bounds for both the potato inspection at Station 1, plus slicing at Station 3 to see if you can identify the problem. Run the numbers from both stations and be sure to get back with me, will you? I need to know which station is out of control.

Stephen Williams - Maintenance

Let me ask you somethin’ – have you ever eaten fried ice cream? They heat that oil to 400 degrees Fahrenheit. I mean it’s hot! Then they drop this cold ball of ice cream covered in slices of pound cake and cinnamon-sugar right into the grease until the whole thing turns brown. Pow. Good stuff, too.

Now you look like a smart fella. Probably thinking to yourself, “I bet they don’t have the oil hot enough to get all the moisture out of the chips.” The problem with that is – fried ice cream sits in oil 50 degrees hotter than ours. And it’s still plenty moist when it comes out.

There’s a few more dynamics ya need to calculate into this conundrum. How thick is that chip? How cold is that potato? How long should the chip remain in that oil? Walk the line. Check the data sheets. You’ll figure it out.

Rajesh Sharma - Vendor

Rajesh is not currently in the facility.

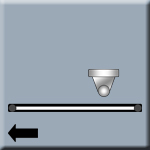

Mike Watts - Inspection

I think you may be onto something. The stale taste that customers are commenting on could be attributed to the raw materials.

I’ll tell you what, these potatoes are supposed to acclimate themselves to the plant temperature over 10 days. They come into the facility at 40 degrees, and we’ve got to let them warm, slowly, to 75. For the last week, I’ve been getting these potatoes with as little as 4 days lead time.

Let’s go check the numbers and see if they were out of bounds when they hit the line.

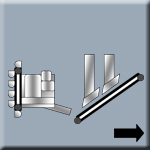

Greg Herman - Peeling

Look here, dude, I’ve been doing this for 3 years now and this is twice in a month you’ve drug your problem into my station. Peeling’s cutters are dialed in and sharp, and don’t have anything to do with stale chips.

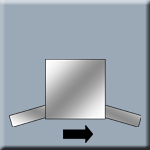

Norma Olson - Slicing

Well hey there, hon! Sound’s like it could be us … if the chips were sliced too thin they could get a crunchy texture that could be mistaken for a stale chip. It sounds like a long shot, but I wouldn’t rule us out. Check this dataset and see how we’re fairing against the 1.5mm target. Bananas! I hope it’s not us.

Bear Hannighan - Frying

Aye, could be frying. But it isn’t … just checked.

Rachelle Scott - Seasoning

Hmm, stale chips? Sounds like not Seasoning. Good luck working it out.

Sandra Deak - Sorting

Wish I could help you, but stale chips doesn’t sound like something we would have a part in. Perhaps talk to Charlie, he’s all I can think of.

Charlie Gomez - Packaging

If Mike thinks the problem could be with us, then I trust his opinion. My crew has some new guys but my boys are good workers and they’re not zombies on the line, they’re focused.

Wait, wait, wait, you said that you sampled some chips in house and they were stale? Well those chips haven’t been off the line long enough to go stale due to packaging … I bet the problem is something else.